Case:How Do We Inspect The Quality Of Used LED displays?

What do you think of the used LED display market?

Everything exists for a reason. Second-hand LED screens also have a share of the market. Because of customer demand, and the specific environment to use used LED display may be more appropriate, also can save money.

But where do these second-hand LED displays come from?

There are a few companies engaged in the recycling and resale of second-hand LED displays. Interestingly, some of these second-hand displays actually come from the manufacturing industry. Excess inventory from large-scale production is a source, and sometimes LED displays that do not meet new product standards can be refurbished to gain a second life.

What factors should you keep in mind when considering purchasing second-hand LED displays?

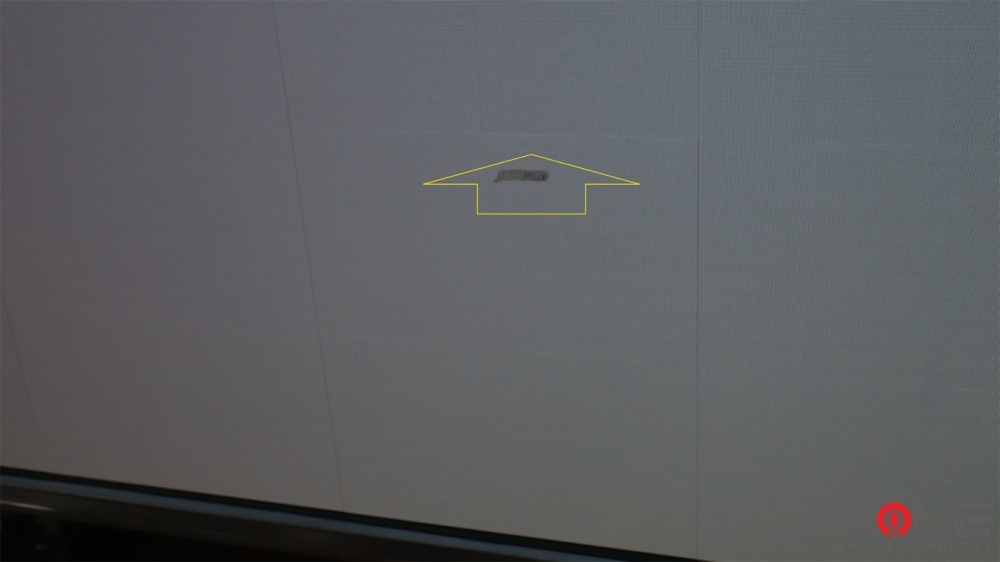

1. Pay attention to the usage traces of LED display. For example, broken lights, dead lights, masks, locks, and cabinet collisions.

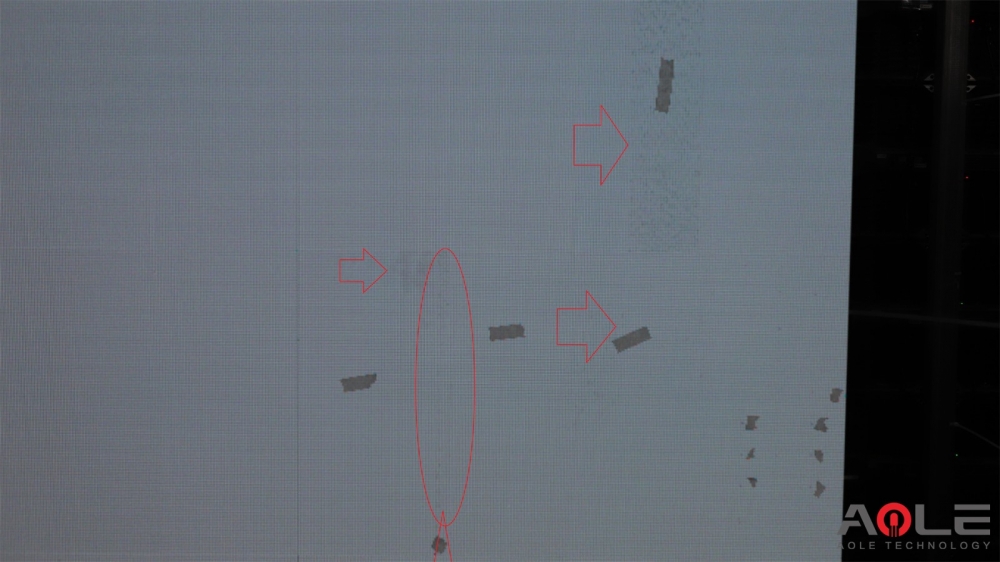

2. Whether the color of the LED display is uniform.

Different chips of LED display after a period of time will appear different degrees of screen and Mosaic phenomenon, this is caused by the LED light attenuation is inconsistent.

3. Safety performance of the LED display screen.

The second-hand LED screen is stored in the warehouse because it is not used for a long time. It is easy to cause other quality problems if not kept properly.

How can Aole help you reduce the risk of purchasing second-hand LED displays?

Here are our suggestions:

To ensure the quality and safety of the second-hand LED display screen you purchased, and to minimize related risks, we suggest that you communicate the following requirements with the seller before final purchase:

1. Comprehensive testing:

Adhere to the requirement to install all LED displays and conduct a 72 hour aging test on them.

2. Before shipping, any existing issues such as masks, LED lights, and IC should be resolved.

These two points are crucial to protect your rights.

How do we check second-hand LED displays?

For second-hand LED screens, our inspection procedures and standards are different from those for new displays. Our comprehensive inspection process covers the following four key aspects:

1. Detailed usage history check:

We carefully inspect the screen for any signs of wear and damage, including issues with lamp beads, string lights, mask integrity, lock function, and cabinet status.

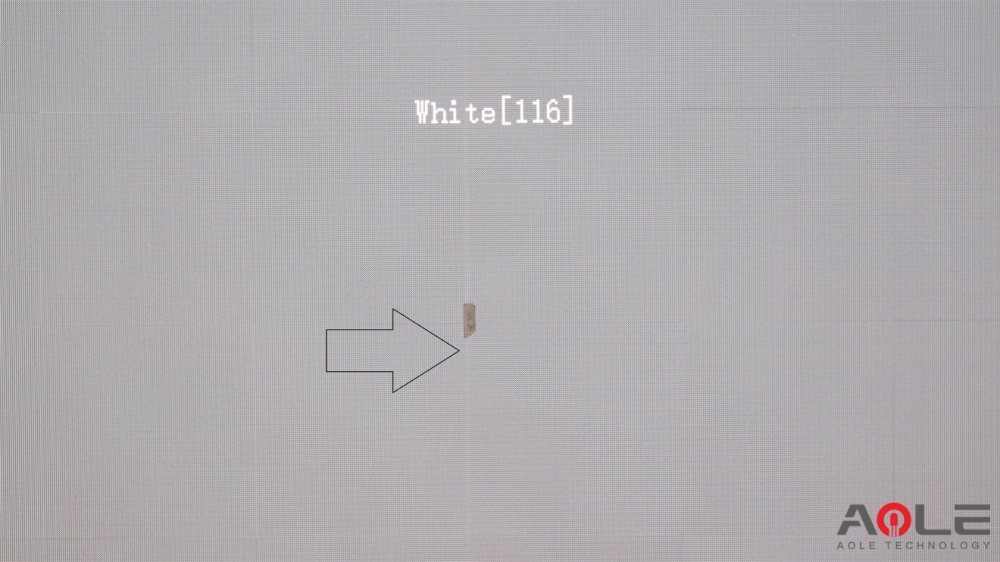

2. Performance testing:

Strictly evaluate red, green, blue, and white elements under different brightness and grayscale settings.

3. Overall quality evaluation:

We evaluate overall performance to identify potential quality risks that may affect your investment.

4. Outdoor LED screen waterproof test:

Conduct waterproof testing on outdoor LED displays to ensure they meet the required standards.

After the inspection is completed, we will provide you with a detailed inspection report within 24 hours. In addition, we can verify whether the supplier has resolved and corrected any display issues before shipment.

Related news

- Aole's Observations on the LED Display Screen Industry

- How To Inspect Outdoor Fixed LED Display Screens?

- Product :What Is The Development Trend Of Naked Eye 3D Displays In 2024?

- Product :How To Choose A Suitable Outdoor LED Display Screen?

- Product : The Higher The Brightness Of The LED Display Screen, The Better? Most People Have Misunderstandings

- Product : How To Choose A Suitable LED Transparent Screen?