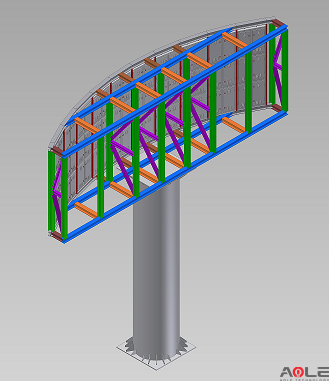

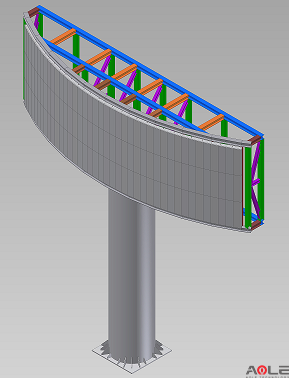

Control points for steel structure construction of curved LED display screens

In the construction of the steel structure of the curved LED display screen, there are some key control points that require special attention to ensure the stability, safety, and aesthetic design of the structure. Here are some suggested construction control points:

1. Arc design planning: Before construction, accurately plan the arc design. Clarify the parameters such as curvature, radius, and center point of the arc to ensure its smoothness and u niformity, in order to meet design requirements.

2. Selection of framework materials: Select high-quality materials suitable for curved structures to ensure sufficient strength and durability. Pay special attention to bending performance to meet the design requirements of curved surfaces.

3. Design of curved support structure: The design of curved support structure is crucial. Reasonably design the components such as beams and columns to ensure that they can evenly withstand the forces of the arc and maintain the stability of the structure.

4. Framework fabrication and connection: During the fabrication and connection of the framework, ensure that the material specifications meet the design requirements and the connection points are stable and reliable. Especially in the arc welding and connection, higher requirements are required to ensure the continuity of the curve and the stability of the structure.

5. Hoisting process: During the hoisting process of the curved LED display screen, professional cranes and hoisting techniques are used to ensure that the display screen and its supporting structure are safely and stably installed in the design position.

6. Overall stability: Through overall debugging and inspection, ensure the overall stability of the steel structure of the curved LED display screen. Ensure that the curved image presented on the display screen is clear and stable.

7. Cable concealment: Reasonably design and arrange the cables to ensure that they can connect to the display screen without affecting the overall appearance. Special attention should be paid to the cable layout in the curved section to maintain overall aesthetics.

8. Wind load assessment: Consider the wind load at the installation site and conduct a reasonable assessment. Ensure that the curved LED display screen can operate safely under various meteorological conditions and avoid structural problems caused by wind.

相关新闻

- Discover the Advantages of Aole's Smart Steel Structures

- Save Time, Build Smart: Aole Indoor Structure Advantage

- AOLE LED Display Intelligent Steel Structure

- Control points for steel structure construction of curved LED display screens

- Construction control points for steel frame of wall mounted LED display screen

- Construction control points for steel structure of column type LED display screen